OUR PAVING INSTALLATION PROCESS

At SD Home Improvements, we follow a strict procedure with every paving job we do. This is to ensure that every one of our customers get a quality finished paving surface that will last for many years to come.

Our aim is with every driveway paving or patio job we do, is to deliver a perfect long lasting job that will guarantee 100% customer satisfaction.

We aim to provide fast, free and accurate on-site design consultations and price estimates. We will guide you through the process every step of the way as we work to transform your existing surface into an amazing outdoor living space. From initial site measurements and contract quotes through the finished surface, SD Home Improvements LTD provide simple, easy-to-understand breakdowns for all services and products so you can make smart, cost effective decisions quickly and accurately.

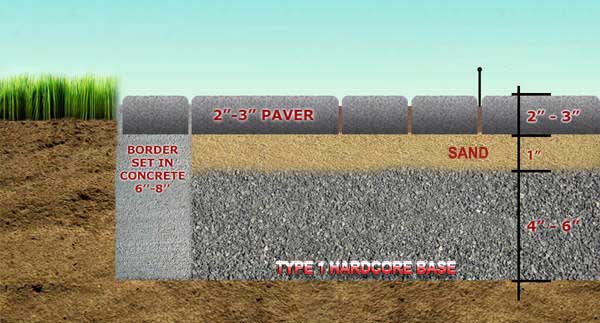

As a standard practice, on all new surface installations, SD Home Improvements excavate approximately 8 inches from the final surface in vehicular traffic areas and 6 inches from final surface in areas trafficked by foot. This is to make sure that whatever happens, your driveway or patio will be locked solid in place.